Rock reinforcement

Reinforce roofs and walls in rock

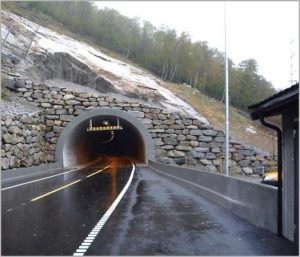

Rock reinforcement refers to the methods used to reinforce roofs and walls in rock. It could, for example, be about mines, tunnels, rock rooms or mountain slopes.

Mines and similar environments that do not have stable walls or roofs can cause great damage to people and property. Therefore, rock reinforcement is a must to reduce the risk of landslides.

Before starting with rock reinforcement, it is important to first analyze the geographical conditions of the area. An evaluation of the bedrock is a prerequisite for starting rock reinforcement.

Rock reinforcement with rock bolts

The rock’s natural fracture system has intersecting cracks that can give rise to intermediate risky wedges in tunnel roofs or walls. By anchoring these wedges with rock bolts into solid rock, they are prevented from falling down and causing damage.

Rock anchoring is used to reinforce the rock’s natural weaknesses in order to provide safe and permanent rock structures and prevent risky wedges in the rock from falling down and causing personal injury or property damage.

Rock bolts usually consist of a steel bar such as reinforcing steel or high-strength tension rods that are anchored in boreholes. The anchorage itself usually consists of cement mortar which transfers the load of the rock to the bolt rod through shearing.

Rock reinforcement with shotcrete

Shotcrete is mainly used for slope stabilization, repair work and as rock reinforcement in e.g. tunnel construction. Shotcrete reinforces the rock through adhesion and mortar action and can interact with rock bolts.

After bolting, the shotcrete is usually sprayed. The thickness of the shotcrete depends on the quality of the rock, the number of cracks and the use of the tunnel or rock room and can vary between approx. 30 mm to 300 mm. In order for the reinforcement to have good durability, the thickness of the shotcrete should not be less than 50 mm.

Dry or wet spraying?

Dry spraying

Generally, no formwork is required when shotcrete is applied, when concrete is shot for tunnels, for example, the rock itself is the form. Only a thin layer of shotcrete is required to achieve a considerable load-bearing capacity, this mainly depends on the shotcrete’s good adhesion to the substrate. However, attention should be paid to the fact that a thin counter-cast concrete has a limited durability.

Concrete spraying can be carried out in two ways. The first and oldest method is called dry spraying, the dry mortar or the slightly pre-moistened mortar is transported using compressed air through a hose to a spray nozzle where water is added directly during spraying before the concrete hits the substrate. Pre-moistened dry use results in less dust spreading. Dry spraying is often used for concrete repairs and minor rock reinforcement work.

Bemix SP40 is a dry mortar used for dry spraying.

Wet spraying

The second method, wet spraying, means that a ready-mixed viscous concrete mass is pumped through a hose. Compressed air is added at the nozzle together with accelerating additives that cause the concrete to stick when, for example, spraying on tunnel roofs. As the concrete mass must be able to be pumped forward from the mixer, it is required that the concrete is sufficiently easy-flowing, which means that the vct must normally be higher than with dry spraying.

How good the sprayability of a shotcrete can be judged based on its ability to stick to the rock surface through both adhesion and cohesion in the concrete mass. Cohesion is the cohesion of the concrete mass that holds the material together. A shotcrete with good sprayability is thus a concrete mass that can be sprayed in thick layers without falling down due to insufficient adhesion or cohesion. The maximum layer thickness indicates how thick a layer can be sprayed before the concrete releases from the rock surface or falls apart due to its own weight.