Impregnation

Why impregnate reinforced concrete structures?

Reinforced concrete structures should be impregnated to prevent degradation of the concrete caused by water and chloride penetration. If the construction is not protected against moisture penetration and harmful chlorides, there is a risk of major damage occurring.

Moisture is a common denominator for the majority of concrete damage and the most common contributing cause to several different types of damage to a reinforced concrete structure.

By stopping or limiting the moisture supply, the following damages can be prevented:

- Without moisture, no frost damage

- Without moisture, no electrolyte during carbonation (reinforcement corrosion)

- Without moisture no transport of salt which leads to salt frost damage

- Without moisture, no reinforcement corrosion when chlorides are mixed in

- Without moisture, no clogging of the concrete’s air pores

About hydrophobic impregnation

Our impregnation products are hydrophobic and silane-based. The silane is the active substance that reacts and creates a water-repellent and water vapor-permeable silicone resin network inside the building material. This is a crucial feature so that outdoor constructions made of reinforced concrete can be protected against moisture penetration and other harmful chlorides but still be able to “breathe” and maintain diffusion openness. It can be easy to think that the solution would be a completely waterproof layer that protects the concrete against the penetration of moisture, but concrete needs to be able to “breathe”. This means that moisture must be able to leave the construction, otherwise there is a risk of damage from other causes such as e.g. frost blasts.

Hydrophobization can be easily explained by the fact that the impregnation applied to the concrete surface makes the hydrophilic (absorbent concrete surface) water-repellent and in that way stops the absorption.

The concrete structure must be dry and free of loose particles. If the concrete is damp, the impregnation cannot penetrate the substrate as intended. The silanes in the impregnation settle on the inner walls of the air pores in the microscopic air bubbles in the concrete. If there is dirt or water in the air pores, the impregnating agent is prevented from penetrating.

In Sweden, water-repellent impregnation agents are used on concrete structures primarily to protect the reinforcement from corrosion as a result of road salt penetration.

.

Standards and requirements to be met for hydrophobic impregnation products

Requirements for plant constructions:

- EN 1504-2, Concrete structures – products and systems for protection and repair – part 2: Surface protection products for concrete (hydrophobic impregnation).

- AMA ANL 23, LFB.311 Protective impregnation of concrete surfaces in bridges against the penetration of chlorides and water.

- NT Build 515, Testing of hydrophobic impregnation for the protection of concrete structures − Prevention of chloride ingress.

Requirements for building constructions

- EN 1504-2, Concrete structures – products and systems for protection and repair – part 2: Surface protection products for concrete (hydrophobic impregnation).

Concrete impregnation of various types

Depending on what is to be impregnated, there are different types of hydrophobic impregnations, either liquids or thickened products which are often called cream or gel. The latter can better remain on the concrete for a longer time, which creates a longer contact time and a normally deeper penetration. The penetration depth is dependent on several factors such as e.g. the concrete quality, moisture contentand and temperature conditions during application.

Impregnation in liquid form

Condur Fluid is applied evenly to the concrete surface in 2-3 layers, and in subsequent layers “wet on wet”. The amount of impregnation depends on the concrete quality and the moisture content of the substrate.

Applied from the bottom up, either with a low-pressure sprayer or low-pressure airless sprayer, brush or roller.

Guideline penetration depth

Condur Fluid with 200 g/m² in 2 layers and on concrete grade C 40/50 Vct 0.45. Penetration depth at 4% moisture: ~5–9 mm. Indicative data only. With more layers, the penetration depth can be increased even more.

Impregnation in cream form

Condur Creme is applied evenly on the concrete surface to the desired layer thickness in 1 layer up to 400 g/m². The amount of impregnation depends on the concrete quality and the moisture content of the substrate.

Applied either with a brush, roller or airless sprayer. When spraying, it is recommended to set a pressure of approx. 40 bar, and increase gradually by 5 bar at a time until the desired result on the spray mist is achieved.

Guideline penetration depth

Condur Creme with 400 g/m² in 1 layer and on concrete grade C 40/50 Vct 0.45. Penetration depth at 4% moisture: ~ 6-11 mm. Indicative data only. With more layers, the penetration depth can be increased even more.

Important with the right conditions and the right temperature conditions

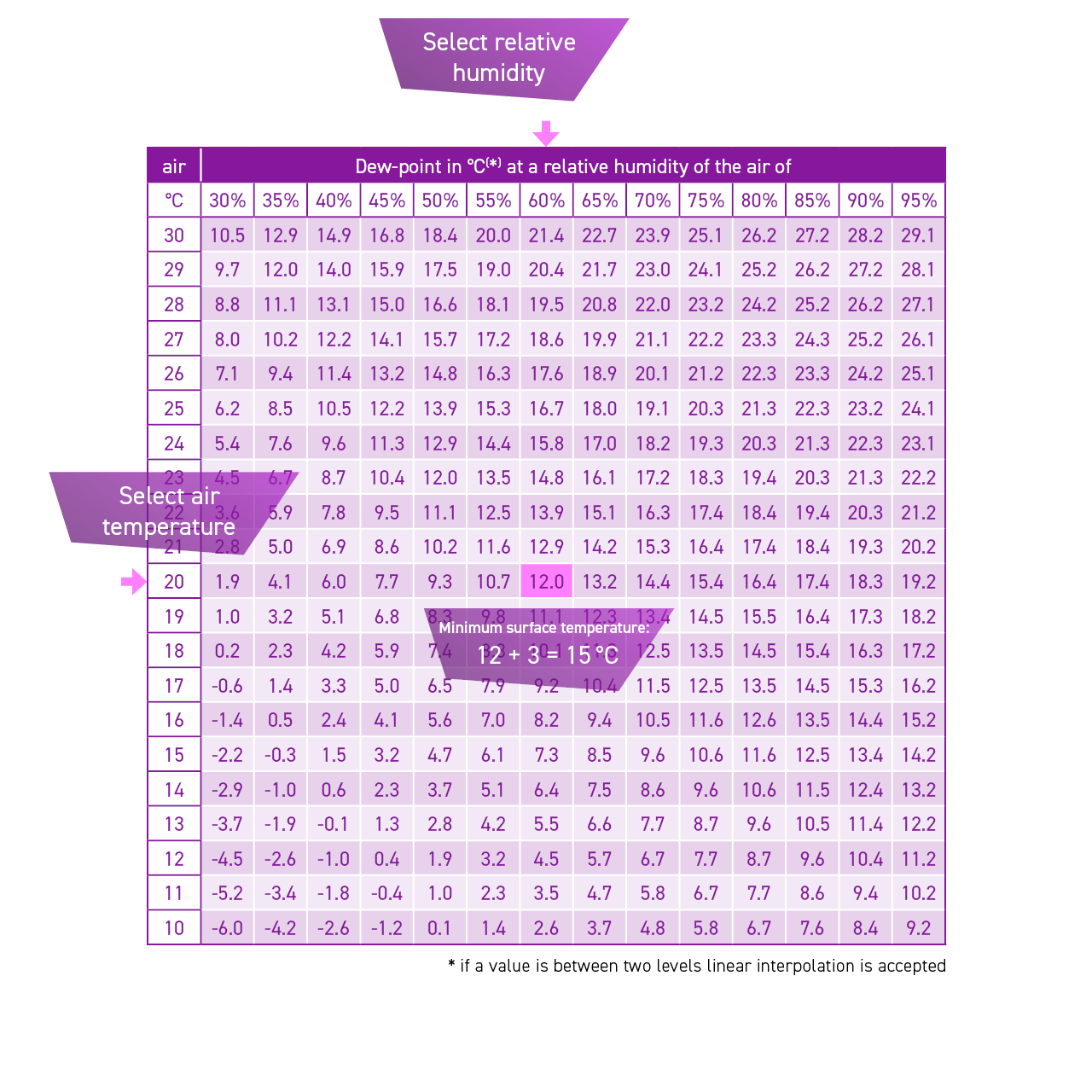

Concrete surface temperature – how is the dew point determined?

General rules:

- During application, the temperature in the air must be at least 5 °C and at most 35 °C.

- During application, the temperature of the surface must be at least 8 °C and at most 30 °C.

- In all circumstances the surface temperature must be 3 °C above the dew point.

Click on the picture to enlarge.

Typical quality control performed on drilled cores

- Water absorption

- Penetration depth

- Chloride penetration

Test areas (1 m²) should be prepared for areas over 500 m². One test per 100 square meters of total surface is recommended. Prepare test areas with different doses to see if requirements are met. Performance can be determined by measuring water absorption or penetration depth (compared to untreated).